GQ150/JM-11 Tubular centrifuge

Separation Factor Fr:15900xg

Motor Power:3 kw

Power Supply:AC380 50Hz

Equipment Weight:700 kg

Drum Inner Diameter:142 mm

Drum Rotation Speed:14000r/min

Solid Volume Capacity:11 liters

Production Capacity:400 - 1500 liters/hour

Water Flow Capacity:1500 liters/hour

Shanghai Junmiao Separation Technology Co., Ltd. GQ150/JM-11 Tubular Centrifuge

I. Main Equipment Parameters

Model | GQ150/JM-11 Tubular centrifuge |

Structure Type | Circular box type front-opening, floor-standing |

Layout Form | Vertical |

Applicable Objects | Pilot-scale stage and industrial production |

Application Fields | Vaccine, pharmaceutical, bio-fermentation, blood products and other industries |

Equipment Material | The parts in contact with materials are made of 316L stainless steel |

Separation Factor Fr | 15900xg |

Motor Power | 3 kw |

Power Supply | AC380 50Hz |

Equipment Weight | 700 kg |

Drum Inner Diameter | 142 mm |

Drum Rotation Speed | 14000r/min |

Solid Volume Capacity | 11 liters |

Production Capacity | 400 - 1500 liters/hour |

Water Flow Capacity | 1500 liters/hour |

Liquid Outlet Diameter | Outer diameter 48mm, inner diameter 44mm |

Feed Inlet Diameter | Outer diameter 12mm, inner diameter 9mm |

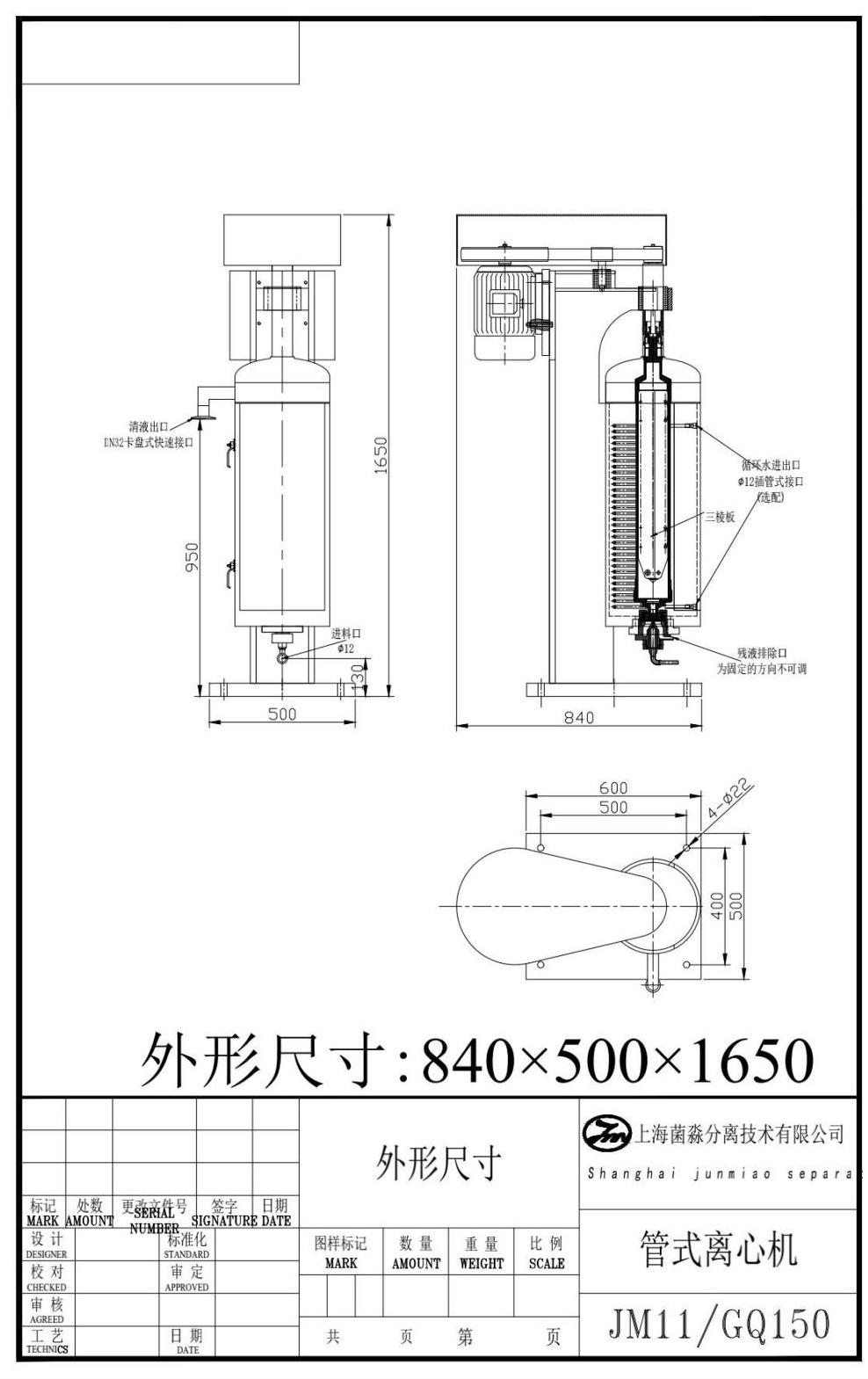

Overall Dimensions | 840 mm× 500 mm× 1650 mm |

Degree of Automation | Continuous feed liquid-solid clarification and separation |

II. Main Equipment Components and Process Requirements

Serial Number | Name of the Complete Host Machine and Standard Accessories | Quantity | Origin | Requirements |

1 | JM - 11 host | 1 set

| Shanghai Junmiao | Plate welding, heat treatment for stress relief twice to ensure the main box body never deforms. The main equipment can be used for more than 15 years. |

2 | Drum | 1 piece | Shanghai Junmiao | All laser welding, internal polishing, each factory-produced drum has a flaw detection report. Stainless steel 316L. |

3 | Feed Pipe | 1 piece | Shanghai Junmiao | Stainless steel 316L |

4 | Liquid Collection Tray Assembly | 1 set

| Shanghai Junmiao | Stainless steel 316L |

5 | Machine Head, Spindle | 1 set | Shanghai Junmiao | 45# steel, 40 chromium, German FAG6204 bearing |

6 | Motor | 1 piece | Jiangsu Dazhong | Jiangsu Dazhong |

7 | Belt | 1 piece | Habasit | Habasit |

8 | Liquid Storage Tank | 1 piece | Shanghai Junmiao | Stainless steel 316L |

9 | Paint Cloth | 2 sets | Shanghai Junmiao | Polytetrafluoroethylene |

10 | M16 × 300 Anchor Bolt | 4 pieces | Shanghai Junmiao | Stainless steel bolt |

III. Cleaning Requirements

The cleaning parts are the parts in contact with the material, including the feed pipe, input pipe, drum,

and liquid collection

tray discharge pipe.

1.It can be rinsed with clean water in a water tank.

2.It can be disinfected with 121 °C steam and washed with hot water.

3.It can be disinfected with alcohol.

IV. After-sales Service and Technical Training Program

1. If the operators in your factory encounter problems that cannot be solved during actual use, we will arrange personnel to

arriv at the site within 24 hours to help your factory solve the problems of the tubular centrifuge. And your factory can also

arrange operators to come to our factory for exchange and study at any time.

2. Technical Training Program

(1) Training Objectives: Normal use of the tubular centrifuge.

Make the operators familiar with the daily use, maintenance and simple repair work of the tubular centrifuge, and ensure the

safe and efficient normal use of the tubular centrifuge in your factory.

(2) Training Objects: The tubular centrifuge operators designated by the company.

(3) Training Contents(Tubular Centrifuge):

1) Explain the separation principle and main functions of the tubular centrifuge.

2) Explain the structure of the tubular centrifuge and the functions of the main components.

3) Demonstrate the daily operation and maintenance of the tubular centrifuge, explain the precautions, and let the operators

operate multiple times under our observation to correct the wrong usage methods.

4) Explain the simple repair work of the tubular centrifuge, including the replacement of consumable parts, various emergency

situations and solutions.

V.Figure:Equipment Structure Diagram

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Mr.Qin

Phone: + (86) 158 2161 9241

E-mail: jmcentrifuge.sales@gmail.com

Whatsapp:8613818500291

Add: 310, Building 1, No. 999 Jiangyue Road, Pujiang Town, Minhang District, Shanghai